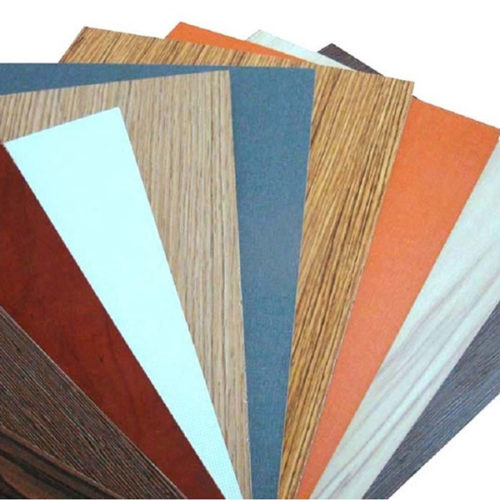

Veneered Panels are made up of a core panel with natural or reconstructed veneer overlaid and pressed onto the core panel. The key feature of these panels is the natural touch and feel, as well as uniqueness, when compared to laminated or Melamine faced panels. The most common core panels used for veneered panels are MDF, Plywood and Blockboard.

Till this day, the veneering process is dependent on highly skilled and experienced labor, despite the adoption of technology to reduce labor and improve product consistency. The most widely used methods for splicing the veneer are plain cut, quarter cut, rift cut, rotary and double cut.

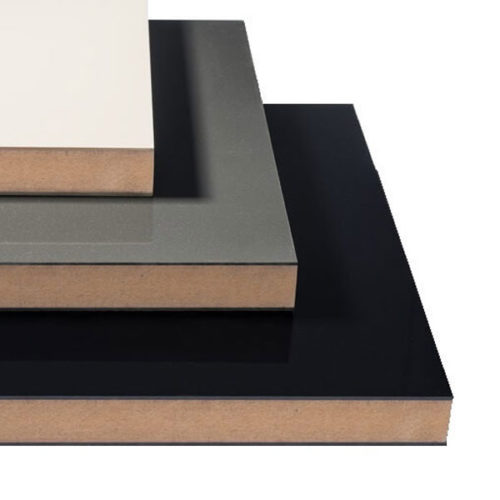

With the increased need for efficiency, cost-cutting with labor and time, carpenter and manufacturers have shifted to finished panels such as Melamine faced panels which require far less processes, time, staff and machinery.

Get Social