-

Frake, also known as Limba is grown in Tropical Western Africa and has a yellowish to golden heartwood, with distinct grey and blacks streaks. The darker figured wood refers to the Black Frake or Limba, While the unfigured refers to White Limba. The sapwood is pale grey and light brown and is not clearly defined form the heartwood. Grain is slightly interlocked with a somewhat coarse texture, displaying some natural luster. Working properties It is easy to work with both using and machine tools, and glues and finishes well. Rot Resistance Frake is considered vulnerable to insect attack and decay.

-

Scientific Name: Acer saccharum Grown mostly in Northeastern America, but unlike most other hardwoods, the sapwood is most commonly used – not its heartwood. The sapwood color ranges from almost white, to a cream color with the heartwood being a darker reddish brown. Hard maple can also be seen with curly or quilted grain patterns. Hard Maple’s grain and texture is for the most part straight, but may be curvy with a smooth texture. Working Properties: Considered easy to work with both hand and machine tools, however it could burn when being machined such as using a router. Glues, and finishes well, though imperfections s can occur when staining, and a pre-conditioner or toner may be needed to get an unified color. Rot Resistance: it is rated as non-durable to perishable, and is quite vulnerable to insect attack

-

Hardboard is a high density and high strength panel is formed with wood fibres and under high temperatures an high pressure compression during a pressing process the degree of pressing involved leads to the high density and hardness, hence the panel’s name. Heat and steam is applied to leave fine, fluffy brown fibres. These fibres are transformed into mats, which are held together with lignum and other glues. Working properties The tempering of the boards achieve great physical and mechanical characteristics and excellent dimensional stability. Hardboard cannot be used outside or in wet applications because it absorbs water.

-

Panels with high gloss finish usually refer to one of three main product sub groups, Acrylic based, PVC (Poly Vinyl Chloride) or UV painted Melamine. These product tiers are generally categorized based on their shine, definition and mirror-like properties, as well as scratch resistance. Working Properties As MDF is the preferred and dominant base panel for high gloss panels, users will benefit from all the favorable features and characteristics of MDF. Woodworking professionals and users will need to take to avoid scratching the shiny surface especially for surfaces that are not anti-scratch by specification. It is not recommended for horizontal use for that reason.

-

This product presents some of the best properties due having plywood used as a core providing excellent mechanical and working properties in addition to wide range of colors and textures. Working properties The plywood core panel will guarantee the durability and excellent machining. High durability provided by the HPL surface which will make it suitable for some of the most abrasive applications. It is a very heavy duty product.

-

Scientific Name: Milicia excelsa Typically found in Tropical Africa, Iroko’s heartwood is usually a yellow / golden or medium brown, with color getting darker over time. Pale yellow sapwood can be clearly told apart from the heartwood. The grain Iroko has a medium texture, with open pores and a slightly interlocked grain. Working Properties: It is easy to work, despite its slightly interlocked grain, with occasional deposits of calcium carbonate which could effect cutting slightly. In terms of gluing an finishing, it is considered good. Rot Resistance: Iroko is very durable, and is resistant to both rot and insect attack; it’s sometimes used as a substitute for Teak.

-

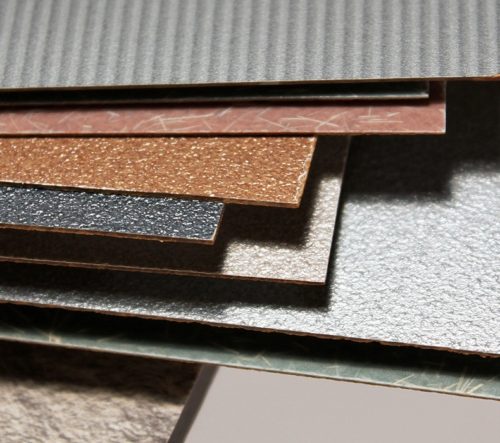

High pressure laminates are made of resin impregnated cellulose where the layer which are combined under heat and high pressure. The kraft paper makes up the core of the material – the substrate. Then there is the overlay paper which gives this material anti-abrasive and scratch properties. And the decorative paper is what gives the laminate the design. HPL is available in an extensive range of finishes and textures. It is the top choice for Decorative laminate if the budget allow and is significantly more durable as a surface when compared more economical alternatives such as Melamine faced. Working properties Hpl should be handled with care, and is more costly and time consuming in order to achieve the finished panel or component compared to other semi finished decorative panels such as melamine faced particleboard. However it is easy to work with and extremely durable, resistant to scratches, abrasion, high impact, heat and chemicals.

-

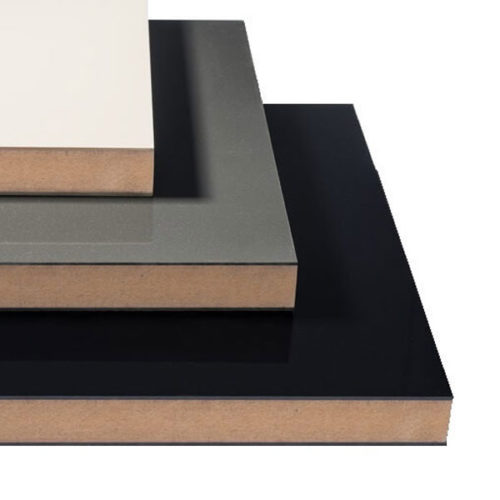

MDF is an engineered wood product made by breaking down hardwood and/or softwood residuals into wood fibers, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF offers extremely high value and excellent for the price when compared with Plywood and Blockboard. Working Properties MDF has a very smooth surface making it excellent for painting and is highly consistent throughout the entire board with no voids or splinters or cracks offering uniquely smooth edges. A key advantage of MDF is that its very Easy to use a router to create endless possibilities of decorative edges. Additional, Band saw or jigsaw easy to use to execute creative designs due to the consistency and smoothness of MDF Some setbacks of MDF include water absorption if not very well sealed from edges. Screwing properties fall slightly short of plywood due to the fine particles that it is made up of. The heavyweight of MDF can make it difficult to use in some applications. As raw MDF, it does not take stain well compared with plywood or blockboard since there is no veneer on the surface.

-

These are panels are laminated with resin-impregnated melamine paper. These panels are available using different core panels from MDF, particleboard, plywood and blockboard Working Properties Different working properties apply depending on the core panel used in the Melamine faced panel. However Melamine faced panels have become increasingly the go to option for manufacturers, carpenters and designers due to the exceptionally broad range of colors, designs and textures with matching edge-banding. Additionally, there have been consistent and rapid improvements in the durability and resistance of these finished panels, as well as innovations in the textures allowing them to mimic real veneer and beyond.

-

Moisture resistant MDF is similar to MDF, but due to an added moisture resistant resin, it can withstand humidity and moisture better than regular MDF. MDF (MR) or commonly referred to as HMR MDF has become in demand in the interior decoration field for the extra much needed feature of moisture resistance. Working Properties The smooth surface makes it excellent for painting and is highly consistent throughout the entire board with no voids or splinters or cracks offering uniquely smooth edges and is easy to use a router to create endless possibilities of decorative edges and to execute versatile designs due to the consistency and smoothness of surface. The heavyweight of MDF -MR can make it difficult to use in some applications.

-

Doorskins are moulded panels, they are made starting with a flat HDF or MDF doorskin that is conditioned with resin, pre-heating, and then pressing the flat sheet between a pair of heated plates in order to transform its shape. The press continuously closes to achieve the molded skin, with the rate of pressing affects the hardness of the final doorskin and achieved the pattern desired. The panels can be painted. Working properties: They are primed for surface protection and can be painted and finished in a variety of ways to achieve the desired look and feel. Assembled using core panels such as Tubular particleboard with foam to give the door strength and stability.

-

Short for Oriented Stranded Board, OSB is an engineered wood-based panel often confused with particleboard. It is formed with strands and flakes of wood in specifically positioned and orientated, compressed and combined with wax and resin adhesives. Working properties The main merits of OSB lie in the field of its mechanical performance, which is directly related to the geometry of the strands and their orientation within the panel. It is strong, dimensionally stable panel that resists well against deflection, delamination, and warping. Relative to their strength, OSB panels are light in weight and easy to handle and install. OSB requires pre-sanding where smooth surfaces are required, and even then it is not the preferred choice when smoothness of surface is a key feature.

Get Social